Since the end of 2019, when the new crown virus broke out, masks and other anti-epidemic materials have become wildly looted items, and there has even been a hard-to-find situation. The price of masks has soared, and even the price of flat masks has exceeded 6 yuan.

Under the strong call of the country, many factories have taken advantage of the domestic manufacturing industry to quickly purchase mask machines for mask production. However, with the increase of mask machine equipment, another problem faced by the industry is the core filter membrane of traditional masks: melt blown cloth has become a popular material, and the price of melt blown cloth materials has soared, even more than 50 per ton. 10,000 market phenomenon-level prices.

In response to the chaos in the entire mask market, today I will use this post to explain the standards of the entire mask market. When everyone talks about buying masks, they say that they want medical masks. But in reality, are medical masks a protective product? Let's compare the national and group standards and overseas standards of masks on the market.

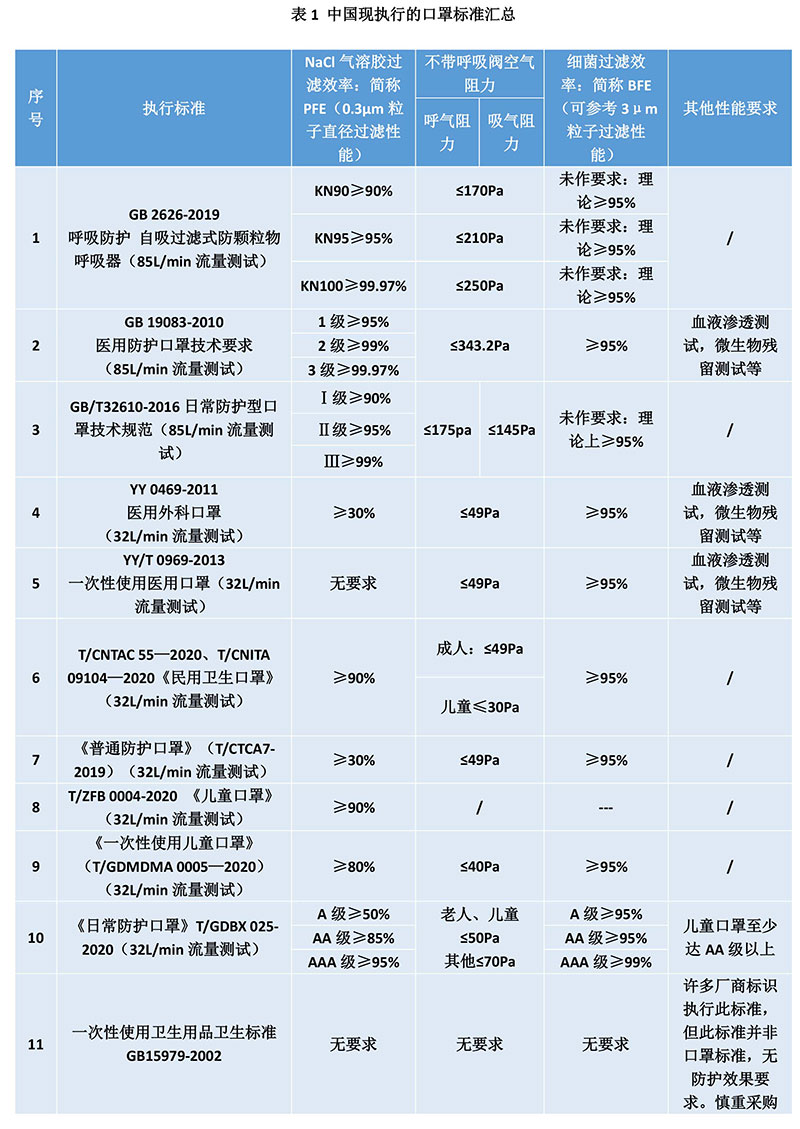

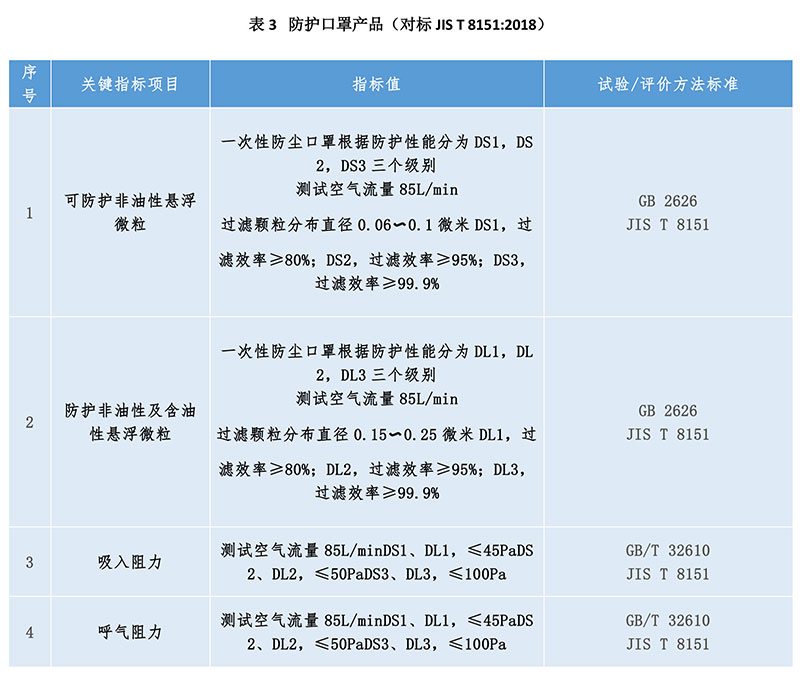

1. Comparison of mask filtration performance standards

Domestic mask filtration performance standard:

How to choose masks and mask filter materials correctly? (figure 1)

As we all know, an important transmission route of the new coronavirus is aerosol transmission. Therefore, when people choose masks, they should pay attention to the filtration efficiency of BFE, as well as the filtration performance of PFE, which directly determines the protective performance of the entire mask.

Through the comparison of the above implementation standards, we can clearly find that the aerosol filtration performance of ordinary people’s protective masks is much higher than that of medical surgical masks and disposable medical masks. Therefore, ordinary people do not need to blindly choose masks. Pursuing medical masks, medical masks emphasize the efficiency of bacterial filtration, but the size of the virus is much smaller than the size of the bacteria. Therefore, the higher the filtration performance of PFE, the better the virus protection effect can be achieved.

civilian mask

International Standard/Overseas Standard:

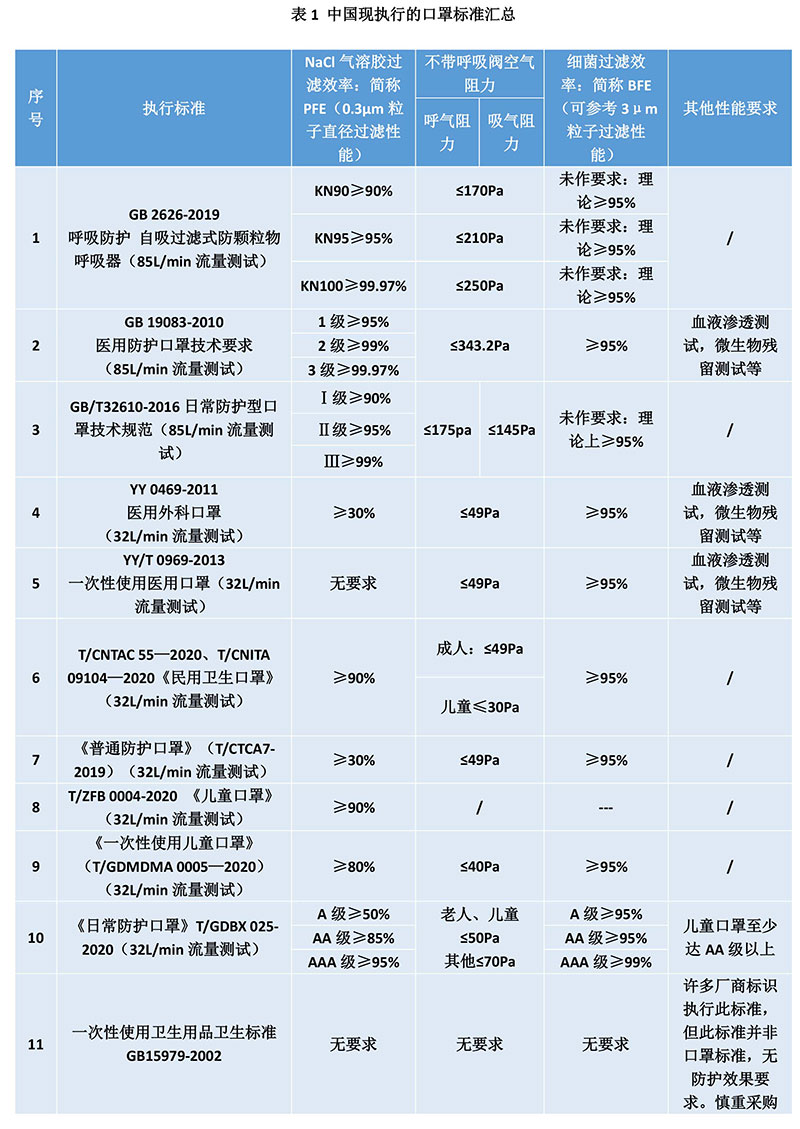

1. American Standard

NIOSH 42 -84 "NIOSH Guide to the Selection and Use of Particulate Respirators" (NIOSH particulate protective mask selection and use guide)

Issued by NIOSH (National Institute of Occupational Safety and Health), it is a technical regulation of the US Federal Regulations CFR, similar to my country’s mandatory standards, the relevant standards (or part of the chapter) and relevant guidelines (or part of the chapter) specified in the CFR, namely Become a mandatory technical specification in the United States. Refer to Table 2 for the benchmarking technical scheme.

How to choose masks and mask filter materials correctly? (figure 2)

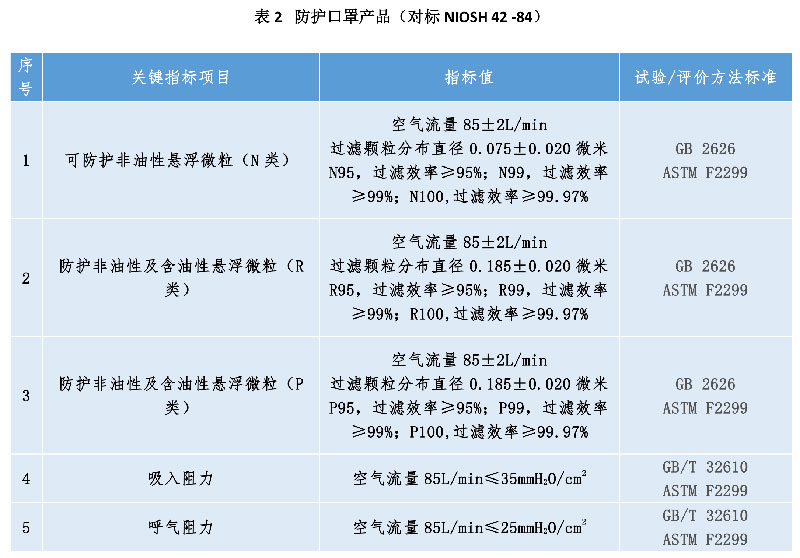

2. Japanese standard

JIS T 8151: 2018 "Particulate respirators" (Particulate respirators)

JIST8151: 2018 is the Japanese national standard, issued by the Japanese Industrial Standards Committee (JISC). Refer to Table 3 for the benchmarking technical scheme.

How to choose masks and mask filter materials correctly? (image 3)

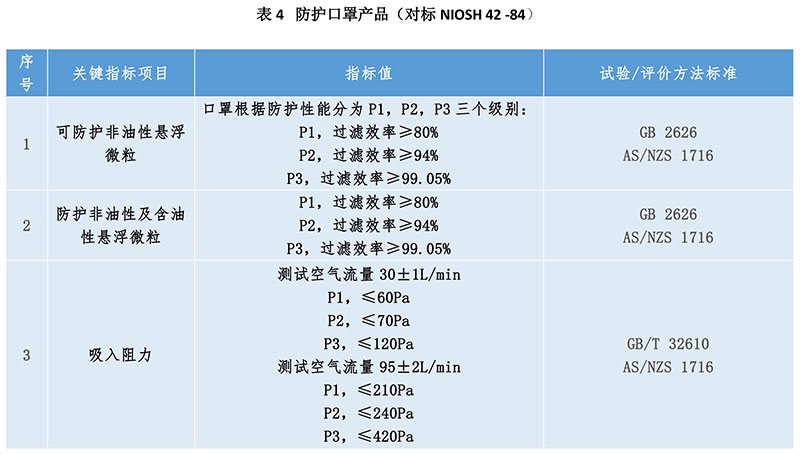

3. Australia and New Zealand standards

AS/NZS 1716-2012 "Respiratory protective devices"

This standard is a national standard used by Australia and New Zealand. Refer to Table 4 for the benchmarking technical scheme.

How to choose masks and mask filter materials correctly? (Figure 4)

Medical masks

The main function of medical masks is to filter particles in the air, blocking droplets, blood, body fluids, secretion droplets, etc. The key technical indicators that play a protective performance in medical masks are the filtration efficiency of particulates and bacteria, and blood penetration resistance .

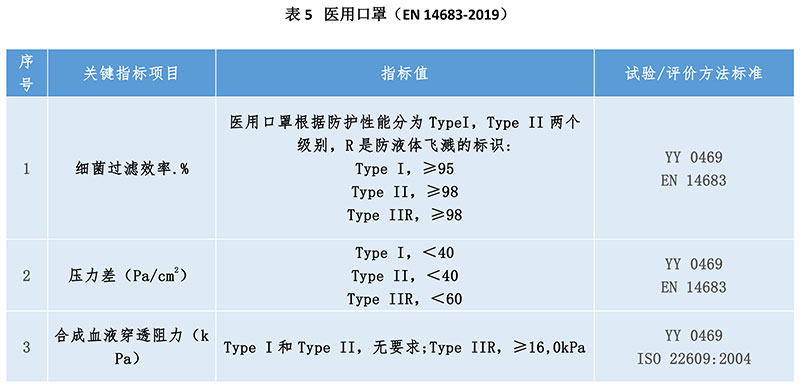

1. European standard

EN 14683-2019 "Medical face masks-Requirements and test methods" (Medical face masks-Requirements and test methods)

This standard is a European standard, formulated and promulgated by the European Committee for Standardization CEN, and implemented in 34 EU countries. The standard itself is not mandatory, but it may be cited by the laws and regulations of EU countries and become the technical regulations (mandatory standards) within each country. ). Refer to Table 5 for the benchmarking technical scheme.

How to choose masks and mask filter materials correctly? (Figure 5)

2. American Standard

ASTM F2100-2019 "Standard Specification for Performance of Materials Used in Medical Face Masks" (Standard Specification for Performance of Materials Used in Medical Face Masks)

This standard belongs to the standards of the American Society for Testing and Materials. The association has a history of 120 years. More than 30,000 members from more than 140 countries have participated in the formulation of more than 12,500 ASTM standards. The ASTM standards are widely used all over the world and become The de facto "international standard" of the industry. The technical scheme is shown in Table 6.

How to choose masks and mask filter materials correctly? (Image 6)

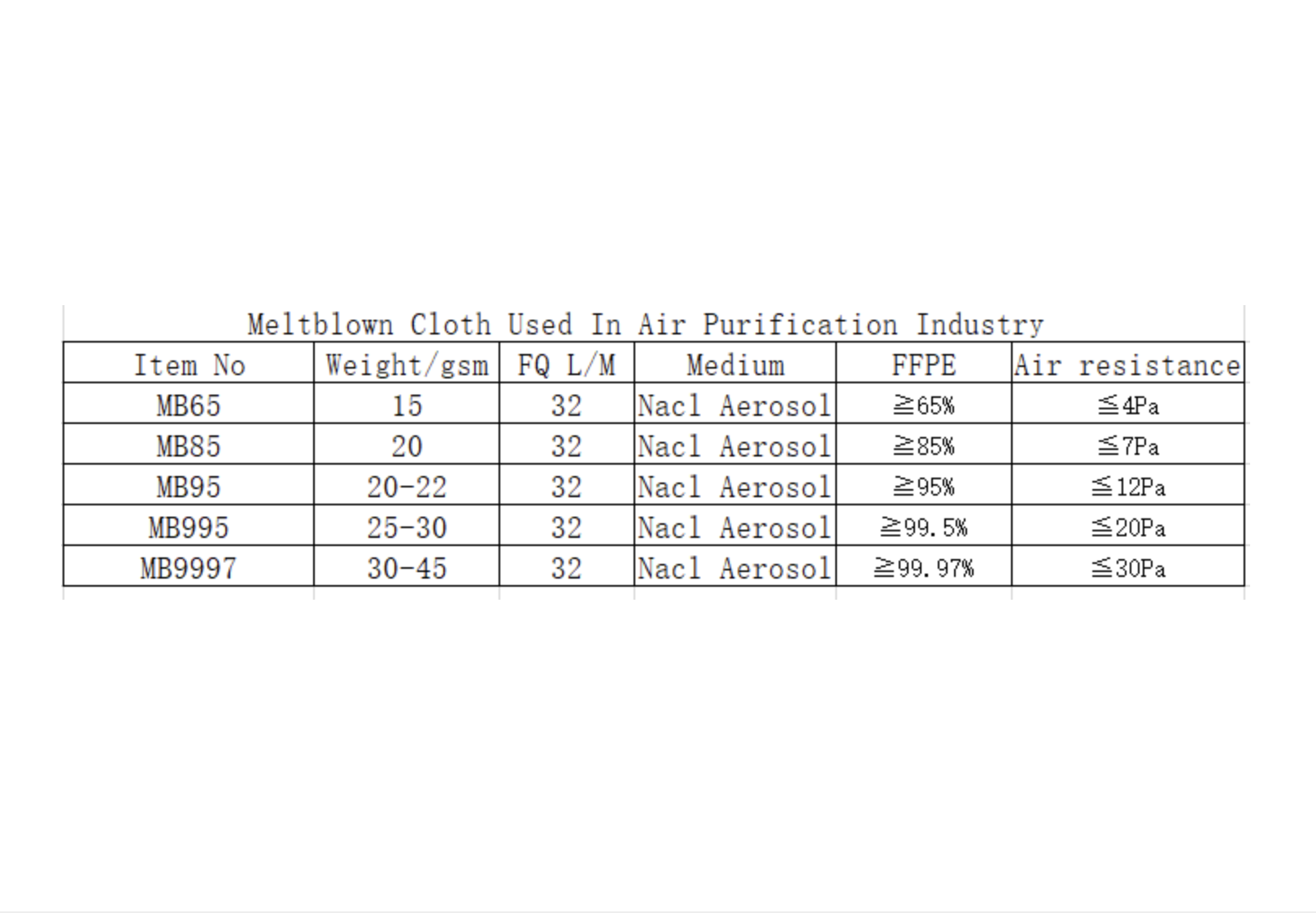

2. Mask filter material selection

Many manufacturers have really experienced twists and turns after purchasing mask machine equipment. First, the purchased mask machine cannot be delivered due to various problems, and secondly, waiting for the mask machine to arrive at the factory. There are various equipment problems, and production cannot be carried out. Faced with the shortage of mask filter membranes, it even reached 500,000+ million/ton.

Some manufacturers happily bought the meltblown cloth and started production and sent it for inspection. As a result, many masks failed. Especially the two standard samples of GB2626 and GB32610 were submitted for inspection. The inspection rate was very low. Especially for N95 masks, there are many unqualified products. Either the breathing resistance is too large or the filtration efficiency is not good enough. The main cause of this problem is the unqualified performance of the filter membrane.

01 Melt blown material

The meltblown material is heated, melted and extruded, and then sprayed out by hot air through the pores of the nozzle. Under the traction and stretching of the hot air, micron or even sub-micron fibers are formed. The accumulation of fibers can form a filter membrane. The melt blown filter membrane of the flat mask is 25g of melt blown material. Before the meltblown material is subjected to electrostatic electret treatment, the filtration efficiency of the meltblown material is relatively low, about 30%-40% of aerosol filtration performance.

If electret masterbatch is added to the spun PP masterbatch, the meltblown cloth material made by electrostatic treatment can greatly improve the filtration performance of the meltblown material, and even a single layer of meltblown material can reach more than 95% Particle filtering performance, but the electrostatic electret process is different from manufacturer to manufacturer. Therefore, the electrostatic retention capacity of melt blown cloth is also different. After most electret materials undergo electret treatment, the filtering performance will quickly decay. Therefore, most of the domestic meltblown materials have extremely poor filtration performance stability. More than 90% of meltblown cloths have a filtration performance of 30%-90% filtration efficiency. Therefore, the quality is uneven, and mask manufacturers are easily affected by Understand the technology and buy fake mask filters. This is why many masks exported from China are not up to standard. The big reason is that the performance of the core membrane material is unstable.

Another water electret process can ensure that the electret on the polypropylene is permanent, the electric field is evenly distributed, and the capture capacity is strong. It is currently a relatively mature technology for preparing high-efficiency and low-resistance meltblown materials. The water electret process can achieve stable N95 material performance at a lower gram weight. However, there are not many water electret equipment in China, and the production capacity is relatively low. In addition, the operating cost of the equipment is also relatively high. Therefore, the domestic Meltblown materials are limited. Many meltblown materials with a BFE of 95% are sold as N95 materials in the market, causing many mask manufacturers who do not understand the market to be deceived.

02 Nano fiber material

Nanofiber material is an emerging filter membrane material. The filtration efficiency of nanofiber mainly depends on physical interception and the van der Waals force of nanomaterials to filter finer particles. It can have higher filtration efficiency for PM2.5 and even PM1.0. Especially for nano-level viruses and other infectious microorganisms, it has a good isolation effect.

Before the epidemic, it was mainly combined with traditional filter membranes to achieve high-efficiency and low-resistance performance. After the epidemic, there was a large shortage of meltblown materials. The prices of meltblown materials soared and the quality was uneven. Therefore, pure nanofiber filter membrane masks were born.

Foshan Lepton Precision Measurement and Control Technology Co., Ltd. quickly launched pure nanofiber filter membranes and production equipment when the meltblown cloth was in short supply, which can produce particulate matter filtration efficiency> 80% (medical surgery is> 30%), BFE filtration efficiency is greater than 98 % (Medical surgery is greater than 95%), the air resistance of the finished mask is 25Pa (medical surgery <49Pa), this nanofiber filter membrane has superior performance, and a single device can meet the filter membrane production requirements of 100,000-120,000 medical masks. The nanofiber masks developed by the Guangdong Provincial Institute of Medical Devices have been tested, and all have reached the filtration performance standards of medical surgical masks. This nanofiber filter membrane is better than 90% of melt blown filter membrane materials on the market. It can be used in "Medical Surgical Masks" YY0469-2011; "Disposable Medical Masks" YY0969-2013; "Ordinary Protective Masks" (T/CTCA7-2019); "Disposable Child Masks" (T/GDMDMA 0005—2020); "CE Standard Medical Mask (EN 14683-2019) and other mask application standards. Avoid the problem of instability of the mask quality caused by the large difference in the quality of the meltblown material filter membrane.

In addition, antibacterial materials can be added in the nanofiber production process, which can effectively kill bacteria and kill viruses. The antibacterial and sterilization efficiency can reach more than 99.95%. It is an important choice for functional masks (such as sterilization, removal of formaldehyde, fragrance, refreshing, etc.), which can realize the coexistence of multiple functions at the same time, providing more choices for the market after the epidemic.

03 Nanofiber electret meltblown material

As mentioned earlier, the qualified rate of domestic N95 mask filters is not high. When making N95 masks, two layers of melt blown cloth are required to be superimposed to achieve the N95 effect stably, but this will inevitably lead to high respiratory resistance and difficulty breathing. problem.

In order to change this phenomenon, Foshan Lepton Precision Measurement and Control Technology Co., Ltd. has jointly developed a high-efficiency and low-resistance filter membrane of nanofiber composite meltblown material. You can choose a layer of 75%-95% meltblown cloth and a layer of nano Fiber can increase the filtration performance of the meltblown cloth to a filtration efficiency of more than 98%, but its air resistance does not exceed 35Pa. Through the control structure, it can even achieve a low resistance membrane performance of 25-30Pa. This is a very good set of parameters for children, the elderly, and sports enthusiasts. The production capacity of this combined technology far exceeds the production capacity of water electret technology, and the energy consumption is far lower than that of water electret equipment. In addition, the functionalization of nanofiber masks can also be realized.

3. Mask recognition

Some time ago, because the supply of masks was in short supply, many people bought fake masks. Therefore, there have been many ways to distinguish the authenticity of masks on the Internet. Some said that the ones that cannot burn are real masks; some said that the ones that are not leaking are real masks; It is a real mask that has difficulty breathing. But is this true to distinguish the authenticity of masks? The answer is that the above method is unscientific. To truly distinguish whether a mask product has protective performance, the main thing is to verify the filtering performance of the mask. Now I will teach you some more scientific methods of identifying the performance of masks.

1. Let the smoking friend take a puff first, then hold it in the mouth, quickly cover the mouth with the mask, and then blow out the smoke. The less smoke from the outer layer of the mask, the better the filtering performance of the mask. Of course, the respiratory resistance must be evaluated at the same time. If the mask emits less smoke, the breathing is smoother, indicating that the filtering performance of the mask is very good. But if there is very little smoke but breathing is difficult, it means that the breathing resistance of this mask is too large and it is not a good mask.

2. Although some masks are very thin and look like fake masks, their filtering performance can be better than most masks. Therefore, the quality of a mask cannot be evaluated solely from its appearance.

3. Comparing the implementation standards, it can be seen from the previous mask standards that it is not that the protective effect of medical masks is good, but it depends on the implementation standards to make a good performance comparison. But this is not to say that the implementation standards marked on the mask packaging box are good references, and you need to look at the comparison of the test reports. Of course, these are not omnipotent. After all, the entire filter membrane market is so messy. Mask manufacturers do not have a stable supply source. The quality of the masks produced varies greatly. Even though all the qualifications are complete, there are problems due to the supply of materials. , Resulting in large differences in the quality of the actual masks produced, and there will be many unqualified products mixed in. So consumers can make a subjective evaluation through the suggestions in Article 1.

4. It is recommended that manufacturers strictly control the product quality of masks, including the quality of the supply of raw materials such as filters. After all, the performance of masks is directly related to the health of consumers. The better the quality, the longer the company will be. It is recommended that mask manufacturers configure corresponding testing equipment for incoming material testing, including: automatic filter material meter, tensile tester, etc.

023-40254665

023-40254665

advisory

advisory